This HACCP checklist follows the seven principles to maintain and manage the HACCP system. Use this HACCP template to evaluate if the HACCP team’s skills and experience are appropriate for the task. This checklist will inspect the products and check if the flow diagram to be used for each product is complete and verified. Moreover, the checklist also covers GMP, cleaning procedures, pest.

Monitoring forms are the foundation of your food safety and HACCP audit evidence. When monitoring forms are completed or filled out they become a record. These records then become your core evidence to prove due diligence along with HACCP compliance. HACCP is a five letter word which starts with H and ends with P. Below is the list of all full forms and acronym of HACCP.

The HACCP system is a team effort, and your HACCP plan is only as strong as your team. Select staff from various departments for your HACCP team. Each HACCP team member should come from a different department to provide a well-rounded approach.

The first group in need of training is the core HACCP team, as they will need a detailed understanding of the hazard analysis process and each step of the assessment. The next training group will be those responsible for conducting CCP controls, as they need to know why they are conducting the check and how to best do so. They will also need to know the consequences of improperly completing. It is still very relevant and can be used as a foundational tool for building your HARPC plan.

We’ve mentioned before that you won’t need to reinvent the wheel here. You can continue to use your HACCP and CCPs but will need to add more structure. The first task in developing a HACCP plan is to assemble a HACCP team consisting of individuals who have specific knowledge and expertise appropriate to the product and process. You usually have to write a plan based on the HACCP principles if you run a food business.

This keeps your food safe from biological. Hazard Analysis and Critical Control Point ( HACCP ) plan. Bu rehbere göretam kapsamlıbir HACCP sistemi özelliklehazırlık, üretimveya işlemefaaliyeti gösterengıdaişletmecileriiçinuygundur. WATSON DairyConsuIting WATSON DairyConsuIting.

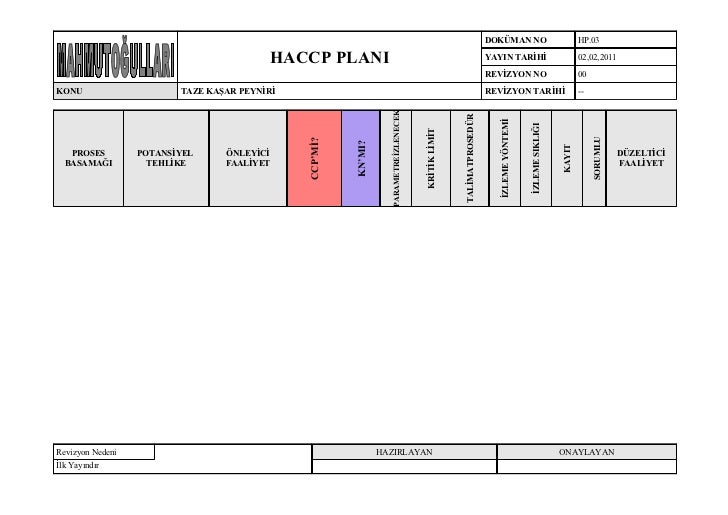

The application of this principle involves listing the steps in the process and identifying where significant hazards are likely to Occur. The HACCP team will focus on hazards that can be prevente eliminated or controlled by the HACCP.

In order to assist Member States and food business operators to better understand the food hygiene rules and how to implement them in specific sectors, a selection of representative full guides at EU and national level for different aspect are made available through the links below. Potrebujem napisat HACCP pre pravadzku na poskytovanie rychleho obcerstvenia a tiez potrebujem nejaky formular, kde sa znaci denne cistenie prevadzky.

Pravidlá a tipy Každý móže napísať len odpoveď. Neskor mozete svoju odpoveď vylep�. Hazard analysis and critical control point ( HACCP ) is a systematic and preventive food safety management system. HACCP helps to determine, prevent and control biological, chemical, and physical hazards in the food processing chain, from the raw material sourcing, production, distribution to final consumption.

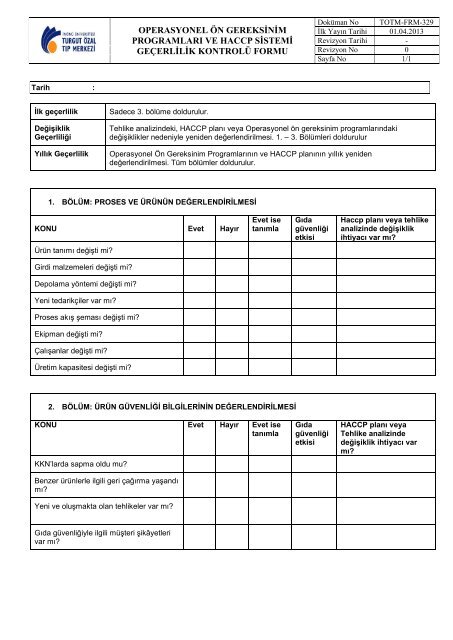

Please note: this is not a complete checklist, but an example of a possible layout that may be used. If you need additional room to document your findings please use additional pages.

It specifies the strategies to be followed to assure control of physical, chemical and biological hazards on the basis of the seven principles of HACCP when manufacturing baked goods. As is the case with any new program launched in the workplace, there is preliminary work required before it can be implemented. Before starting a HACCP plan, these steps must be completed: 1. Choose a HACCP coordinator and team. In some cases, the best candidate for this important position is clear.

A company may select a quality control. HACCP ’ is a systematic way of analysing the potential hazards in a food operation, identifying the points in the operation where the hazards may occur, and deciding which points are critical to consumer safety. These are the critical control points (CCP’s).

For the successful implementation of HACCP based procedures, appropriate documentation and records must be kept and be readily available. It is unrealistic to operate HACCP based procedures or to demonstrate compliance with the current legislation without providing evidence such as written records.

As with the HACCP based procedures themselves, the complexity of the record keeping will very.

Hiç yorum yok:

Yorum Gönder